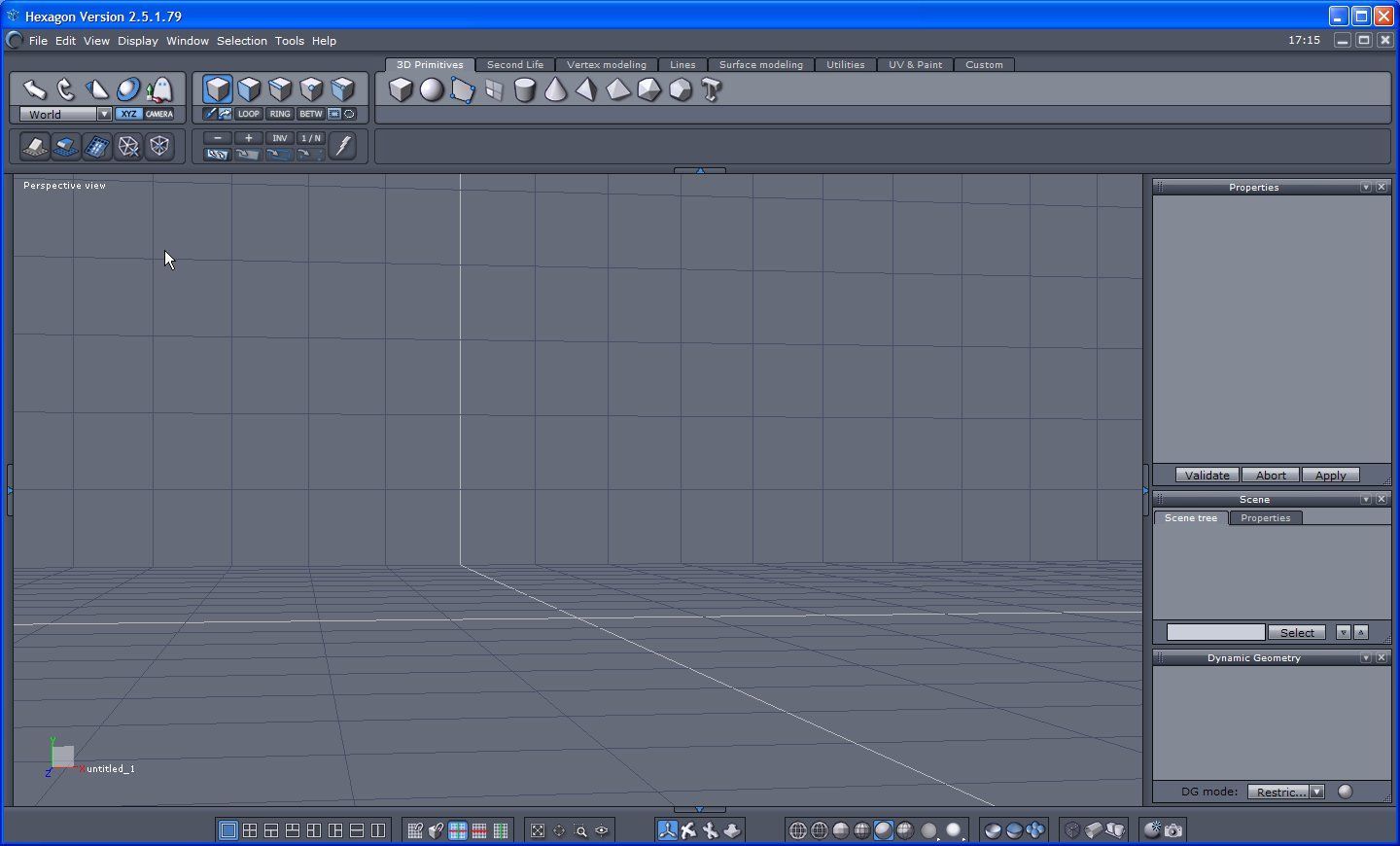

“Meltio has already provided equipment to Hexagon and our engineering teams are working together to deliver the best turnkey post-processor for supported CNC systems.” A hybrid manufacturing setup with ESPRIT software and the Meltio Engine. “The Meltio DED Technology provides a tremendous advantage for users who want high-quality AM processes without the high capital investment in new machinery,” said Clément Girard, Product Manager responsible for Additive Manufacturing CAM at Hexagon’s Manufacturing Intelligence Division. Through the deal, Hexagon becomes the first hybrid manufacturing software partner for the Meltio Engine and furthers the system’s hybrid manufacturing capabilities for parts produced via a combination of direct energy deposition (DED) and machining. As we develop this approach further, our experience of leveraging data from all phases of the manufacturing process will help create the Autonomous Connected Ecosystems (ACE) that will enable Smart Factories.3D printer manufacturer Meltio has integrated ESPRIT TNG hybrid manufacturing CAM software from Sweden-based global technology company Hexagon into its Meltio Engine system. Norbert Hanke, president of Hexagon’s Manufacturing Intelligence division, adds, “The formation of the Production Software business complements our design and engineering and metrology businesses, enabling us to build unique solutions for our customers in manufacturing. We’re all excited at the prospect of what’s possible now creating innovative manufacturing intelligence solutions in the production software space.”

Our technology experts from Vero, FASys and SPRING have been working very closely together for some time, so operating together as a single entity is a natural step for us. “We’re increasingly focused on developing product synergies that will help customers improve quality and productivity. “Over the last five years our available technology and solutions have evolved considerably from the CAD CAM heritage of Vero,” explains Steve Sivitter, CEO of the Production Software business. Combining components of this technology portfolio has allowed Hexagon to develop solutions for reverse engineering and on-machine measurement. SPRING Technologies, acquired in 2018, provides CNC simulation technology for G-code verification and workflow optimization.

The 2017 acquisition of FASys brought tooling and resource management software and shop-floor automation and integration expertise into the portfolio.

Hexagon acquired Vero Software, a specialist in CAD CAM software, in 2014. 7 the formation of its Production Software business, comprising Vero Software (Gloucestershire, UK), FASys (Cologne, Germany) and SPRING Technologies (Boston, MA, US). Hexagon Manufacturing Intelligence (North Kingstown, RI, US) announced on Jan.

0 kommentar(er)

0 kommentar(er)